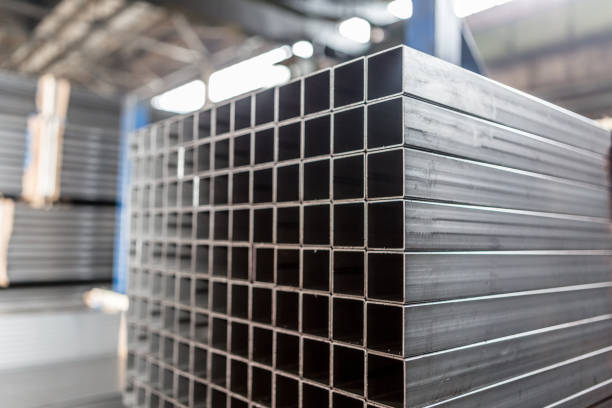

Square Steel Tubing: The Structural Backbone for Modern Engineering

- miles olsen

- Business

- 2025-07-08 16:17:36

- 347K

In creation, production, and structural design, rectangular metal tubing is one of the maximum relied on and widely used substances due to its particular mixture of strength, precision, and aesthetic appeal. Known for its easy traces, high load-bearing ability, and uniformity, square tubing plays an important role in the entirety from steel frameworks to precision equipment. As industries searching for materials that balance capability with design, square metal tubing has come to be the go-to answer for dependable and long-lasting effects. Reliable providers, including names like Texas Iron and Metal, have long recognized the significance of top notch rectangular tubing in infrastructure and business innovation.

What Makes Square Steel Tubing Different

Defining Features and Structural Benefits

Square metallic tubing is fabricated with a rectangular hole and manufactured in diverse wall thicknesses and sizes to meet specific engineering needs. Unlike spherical tubing, the flat facets of rectangular tubing permit for easier welding, alignment, and integration into load-bearing structures. Its geometry allows for more torsional resistance and multi-directional electricity, giving it a structural area in both vertical and horizontal applications.

Uniform Strength and Durability

The constant shape of square tubing guarantees even distribution of strain along all four facets. This uniformity enhances the fabric’s potential to resist bending, buckling, and torsion. In initiatives that involve each structural integrity and visible presentation, rectangular tubing keeps power with out compromising on clean aesthetics.

Square Steel Tubing in Industrial and Commercial Applications

Construction and Framing Projects

One of the maximum not common uses of rectangular metal tubing is in building frames for residential, commercial, and industrial structures. The material offers a balance of weight and energy that makes it best for columns, beams, and horizontal supports. Because of its compatibility with concrete and other structural additives, rectangular tubing is frequently discovered within the skeletons of current homes.

Agricultural Equipment and Fencing

Square tubing is extensively used in agricultural packages where power and sturdiness are critical. From machinery frames to cattle enclosures and irrigation supports, its resistance to corrosion and simplicity of welding make it a long-lasting preference. It is designed to handle outside conditions at the same time as minimizing protection and upkeep over time.

Furniture and Architectural Design

In the arena of interior and outdoor layout, square tubing has come to be a staple for furniture, railings, staircases, and decorative elements. Its glossy, geometric appearance aligns with modern-day aesthetics, while its structural talents ensure lasting performance. Architects and designers frequently choose square tubing for installations in which look is as vital as functionality.

Fabrication Advantages of Square Steel Tubing

Easy Cutting, Bending, and Welding

Steel fabricators respect rectangular tubing for its adaptability. The flat surfaces make it less complicated to align and be a part of the usage of welding or fasteners, reducing production time. Its compatibility with laser slicing and automated machinery permits for precision fabrication with minimum waste. Whether a project requires a straight edge, a smooth bend, or a cutout, rectangular tubing can be shaped without compromising electricity.

Customization Options

Square metallic tubing is available in a couple of grades and finishes to meet the needs of numerous industries. Hot-rolled, bloodless-rolled, and galvanized finishes provide exceptional tiers of electricity, look, and corrosion resistance. Custom length, diameter, and wall thickness options ensure that every piece may be tailor-made to a assignment's specifications, lowering the want for extra processing on-web site.

Why Engineers Prefer Square Steel Tubing

Strength-to-Weight Efficiency

Square metal tubing gives one of the great electricity-to-weight ratios in the enterprise. Its hollow layout minimizes fabric utilization whilst maximizing structural overall performance. This mixture makes it best for large-span systems or frameworks where weight financial savings make a contribution to safety and performance without compromising durability.

Load Distribution and Torsional Resistance

The symmetrical shape of rectangular tubing allows it to distribute hundreds lightly and face up to torsion. This characteristic is essential in systems subject to dynamic forces together with wind, movement, or vibrations. It also complements stability in architectural and mechanical programs, making it a reliable desire for both static and kinetic environments.

Environmental and Economic Benefits

Recyclability and Low Environmental Impact

Steel is one of the maximum recycled materials on the earth, and square tubing is no exception. At the give up of its lifecycle, it is able to be repurposed with out losing its structural integrity. This reduces the call for for brand spanking new raw materials and supports environmental initiatives in construction and manufacturing. Recyclable steel tubing aligns with inexperienced building certifications and reduces the overall carbon footprint of any task.

Long-Term Cost Savings

The sturdiness of square steel tubing way fewer upkeep, replacements, or maintenance fees over the years. Its resistance to environmental degradation and mechanical wear extends the usable lifestyles of any structure, saving cash on future interventions. For organizations and developers centered on long-time period ROI, rectangular tubing provides a value-effective investment.

Factors to Consider When Choosing Square Steel Tubing

Size and Wall Thickness

Selecting the appropriate dimensions is important for performance. The outer length and wall thickness decide the electricity and pressure of the tubing. Engineers have to assess load requirements, environmental situations, and pressure points to identify the proper specifications for each software.

Steel Grade and Finish

Different metal grades provide varying stages of electricity, flexibility, and corrosion resistance. Projects requiring publicity to moisture or chemical substances can also require galvanized or chrome steel tubing. Cold-rolled tubing, however, offers tighter tolerances and a smoother end, making it suitable for precision packages.

Certification and Quality Control

High-nice rectangular steel tubing ought to meet enterprise standards, along with ASTM, A500, and different structural specs. Reputable suppliers offer material certification and checking out information to verify that the tubing meets safety and performance requirements. These assurances are specifically important for authorities or high-risk production initiatives.

Supporting Innovation with Square Tubing

Integration in Automated Fabrication Systems

The clean geometry of square tubing makes it perfect for use in automated fabrication structures. It is well suited with robotic welding, CNC machining, and modular construction techniques. These technologies reduce exertions time and make sure better accuracy in assembly, improving both high-quality and productivity.

Adapting to Modern Construction Trends

As modular creation and prefabricated systems come to be more not unusual, square tubing is increasingly used to create frameworks that are strong, lightweight, and easy to move. Its adaptability lets in it to assist everything from temporary installations to permanent excessive-upward push systems, making it a bendy fabric for a extensive variety of architectural visions.

Importance of Local Supply and Distribution

Reduced Lead Times and On-Demand Fulfillment

Access to a regular deliver of rectangular metallic tubing is crucial for uninterrupted assignment timelines. Local providers provide faster shipping, better stock control, and real-time order changes. This proximity to the job web page reduces logistical complexities and permits for extra agile creation workflows.

Technical Expertise and Customer Support

Working with regional providers inclusive of Texas Iron and Metal, offers the added benefit of expert consultation. From product choice to fabrication recommendation, their knowledge of local production practices and compliance standards supports smoother procurement and execution. This aggregate of fabric availability and technical aid guarantees that projects stay on time and within price range.

FAQs About Square Steel Tubing

What is square metallic tubing used for in creation?

Square steel tubing is normally used for framing, supports, railings, and structural reinforcements. Its power and symmetrical shape make it perfect for each vertical and horizontal load-bearing programs.

How does square tubing evaluate to round tubing?

Square tubing gives flat surfaces for easier fabrication and alignment. It also has extra torsional resistance, which is useful in systems requiring multi-directional energy or unique welding.

Can rectangular metal tubing be used outdoors?

Yes, while properly completed or galvanized, rectangular metal tubing can face up to outside publicity. It is extensively utilized in fencing, signage, and structural helps in outside environments.

Is square tubing recyclable?

Square metal tubing is fully recyclable and regularly made with recycled metallic. Its sustainability and coffee environmental impact make it suitable for green production tasks.

What sizes are available for rectangular metal tubing?

Square tubing is available in a whole lot of sizes, wall thicknesses, and grades. Custom fabrication is regularly to be had to fulfill precise challenge necessities and overall performance standards.

Leave a Reply

Please login to post a comment.

0 Comments