Step-by-Step Guide to Isolator and MCB Connections

- harsh arora

- Business

- 2025-11-04

- 2163K

In modern electrical systems, safety, efficiency, and reliability are of utmost importance. Both residential and industrial setups depend on robust electrical protection to prevent hazards, equipment damage, and operational downtime. Among the essential components in any electrical distribution system are isolators and Miniature Circuit Breakers (isolator MCB connection). These devices play critical roles in ensuring that electrical circuits remain safe while allowing for easy maintenance and efficient operation. Understanding how to properly install and integrate isolators with MCBs is crucial for electricians, engineers, and homeowners alike.

What Is an Isolator?

An isolator is a manually operated switch designed to disconnect a circuit or equipment completely from the power supply. Unlike circuit breakers, which automatically trip under fault conditions, isolators are primarily used to ensure the safety of personnel during maintenance or repair work. By providing a visible break in the circuit, isolators guarantee that no electrical current flows through the disconnected section, allowing technicians to work safely without risk of electric shock.

Isolators are commonly used to isolate motors, transformers, and other high-voltage equipment. They are an essential safety feature in industrial setups and commercial buildings, where maintenance and emergency disconnections are frequently required.

Understanding Isolator MCB Connection

The isolator MCB connection combines the safety function of an isolator with the automatic protective function of an MCB. MCBs, or Miniature Circuit Breakers, automatically disconnect electrical circuits in the event of overloads or short circuits. When connected in conjunction with an isolator, MCBs allow the circuit to be manually isolated for safety, while also providing continuous protection against electrical faults.

The isolator MCB connection ensures that equipment is both safely isolated during maintenance and automatically protected during normal operation. This combination is especially useful in industrial, commercial, and residential applications, where both safety and operational reliability are critical.

Differences Between Isolators and MCBs

Although both isolators and MCBs are essential electrical safety devices, they serve different purposes:

- Operation: Isolators are manually operated and should not be used to switch live loads, while MCBs automatically trip under abnormal conditions.

- Purpose: Isolators provide safe maintenance by disconnecting power, whereas MCBs protect circuits from overcurrent, overloads, and short circuits.

- Functionality: MCBs operate automatically in response to electrical faults, while isolators require human operation.

Understanding these differences is important for correctly designing and installing electrical systems that combine safety and protection effectively.

Benefits of Integrating Isolators with MCBs

Using an isolator together with an MCB offers several key advantages:

- Enhanced Safety: The combination ensures that circuits can be safely disconnected for maintenance while remaining protected from electrical faults during operation.

- Reliable Circuit Protection: MCBs automatically disconnect circuits during overloads or short circuits, preventing damage to appliances and wiring.

- Convenience: Isolators provide a visible break in the circuit, making maintenance and troubleshooting easier and safer.

- Reduced Downtime: Faulty circuits can be isolated and repaired quickly, minimizing disruptions in industrial and commercial operations.

- Extended Equipment Lifespan: By preventing overcurrent damage and ensuring safe maintenance, the isolator MCB connection helps extend the life of electrical devices.

- Compliance with Standards: Proper integration ensures adherence to electrical safety codes and industry best practices.

Step-by-Step Guide to Installing Isolator and MCB Connections

Correct installation of an isolator MCB connection is crucial to ensure safety, efficiency, and reliable operation. The following steps provide a comprehensive guide:

Step 1: Planning the Installation

Start by assessing the electrical system, load requirements, and the circuits that need protection. Determine where isolators and MCBs should be installed for optimal safety and accessibility. Proper planning also helps in selecting the appropriate current rating and type of devices.

Step 2: Power Shutdown

Before starting any installation work, ensure that the main power supply is completely switched off. Use a voltage tester to confirm that the circuits are de-energized, eliminating the risk of electric shock during installation.

Step 3: Selecting Appropriate Devices

Choose an isolator and MCBs that match the system voltage, current rating, and load type. For example, high-power motors or industrial machinery may require higher-rated MCBs, whereas residential circuits may use lower-rated devices. Always select high-quality components from reputable manufacturers to ensure reliability and compliance with safety standards.

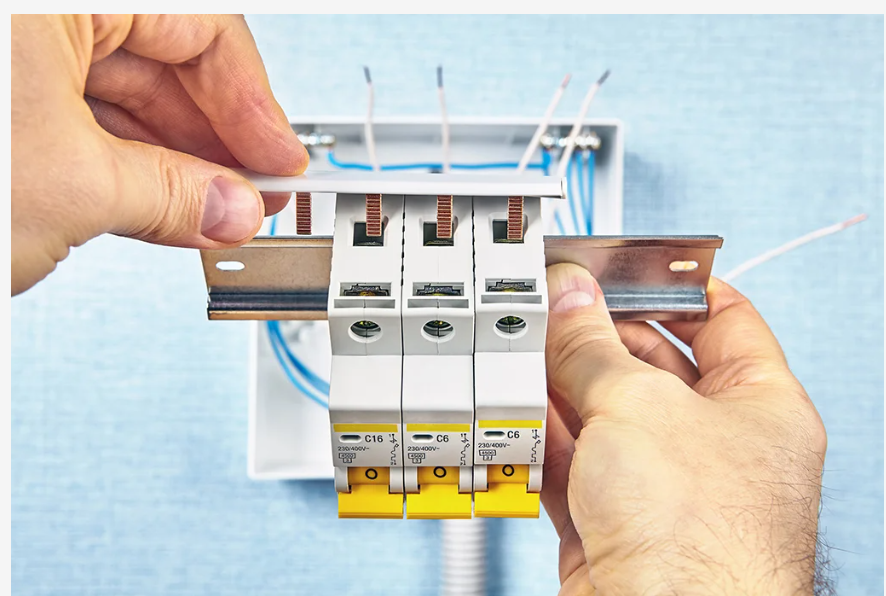

Step 4: Mounting the Devices

Securely mount the isolator and MCBs on a DIN rail or panel board. Maintain adequate spacing between devices for heat dissipation and easy access during maintenance. Correct placement ensures safe operation and convenient troubleshooting.

Step 5: Wiring the Isolator MCB Connection

- Connect the incoming supply to the isolator, which acts as the main switch for the circuit.

- From the isolator, connect the outgoing wires to the MCBs. This isolator MCB connection ensures that circuits are protected automatically while remaining manually isolatable.

- Tighten all connections to prevent loose terminals, which can lead to overheating, arcing, or electrical faults.

Step 6: Grounding and Neutral Connections

Proper grounding is essential for safety. Connect the neutral and earth wires according to standard electrical codes. Ensure that the isolator and MCBs are grounded to prevent electric shock and equipment damage.

Step 7: Testing the System

After installation, switch on the main power supply and test the isolator MCB connection. Operate the isolator to ensure smooth manual operation and check the MCB by simulating overload conditions to confirm it trips correctly. Proper testing ensures the safety and functionality of the system.

Step 8: Regular Maintenance

Routine maintenance ensures long-term performance and safety:

- Inspect isolators and MCBs for wear, damage, or discoloration.

- Test the devices periodically to ensure correct tripping and operation.

- Clean contacts to maintain proper electrical conductivity.

- Check for tight and secure connections.

- Monitor load conditions to prevent frequent tripping or overloading.

Proper maintenance guarantees reliable circuit protection and minimizes potential hazards.

Applications of Isolators and MCB Connections

The isolator MCB connection is versatile and widely used across various applications:

- Residential Buildings: Protecting lighting circuits, air conditioners, kitchen appliances, and other household devices.

- Commercial Buildings: Ensuring safe operation of office equipment, HVAC systems, and lighting networks.

- Industrial Facilities: Safeguarding motors, machinery, and control panels from electrical faults.

- Renewable Energy Systems: Protecting solar inverters, battery storage systems, and auxiliary circuits.

- Data Centers: Maintaining safety for server racks and critical IT equipment, reducing the risk of downtime caused by electrical faults.

These applications demonstrate the importance of integrating isolators and MCB connections to ensure safe and reliable electrical systems.

Advantages of Proper Integration

Integrating isolators with MCBs provides several advantages for electrical systems:

- Clear isolation points for maintenance personnel.

- Reduced risk of electrical accidents.

- Optimal protection for sensitive and high-power equipment.

- Compliance with safety standards and regulations.

- Simplified troubleshooting and maintenance for technicians.

Proper integration ensures that electrical systems remain safe, efficient, and reliable, reducing downtime and operational disruptions.

Conclusion

Installing and properly connecting an isolator with MCBs through a correct isolator MCB connection is essential for safe, reliable, and efficient electrical systems. Isolators provide manual safety disconnection, while MCBs protect circuits automatically from overloads and short circuits. Together, they enhance system safety, reduce downtime, and prolong the lifespan of electrical equipment.

Lauritz Knudsen Electrical and Automation offers a wide range of high-quality isolators and MCBs designed for maximum safety, durability, and reliable performance. With their advanced electrical solutions, the company ensures that residential, commercial, and industrial systems operate safely and efficiently, providing an uninterrupted and secure power supply across all applications.

Leave a Reply

Please login to post a comment.

0 Comments